Services

Engineering. Production. Supply.

How we support

We provide full support from a single source. So you can stay focused on your core business.

Idea Finding & Problem Solving

We support you from the first idea to a workable concept.

Rapid Prototyping & Samples

Test and improve quickly with functional prototypes.

Design for Manufacturing

Designs, which are easy to produce, considering the selected manufacturing method.

Design for Costs

Optimized design for costs, considering materials, machines and methods.

Manufacturing

State on the art production environments for high quality serial productions.

Assembly

Support for sub assemblies based on work-instructions and assembly plans.

Testing

Environmental, functional testing, dimension recording to ensure reliability and compliance.

Quality Assurance

Quality Assurance in every production step.

Logistics

On time shipping and full logistic support.

Our manufacturing capabilities

A wide range of manufacturing processes for cost-effective components and reliable results.

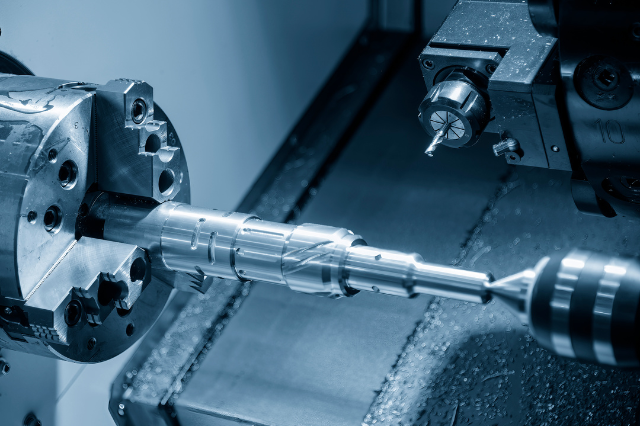

CNC machining

We use multi-axis milling and turning processes supported by a range of machine tools to produce precise components for prototypes and series production. We machine aluminum, steel, stainless steel, and various other metals as well as plastics according to your specifications.

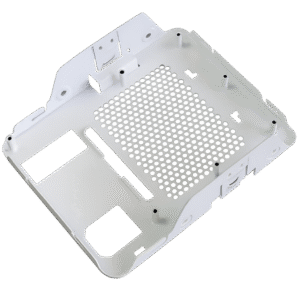

Sheet metal processing

We produce sheet metal parts using laser cutting, punching, bending, and forming. Components can be manufactured with integrated inserts, standoffs, or customized fastening elements. Depending on the requirement, these elements are pressed in or welded. This is how we ensure a clean and precise integration of PCBAs or additional assemblies into the housing.

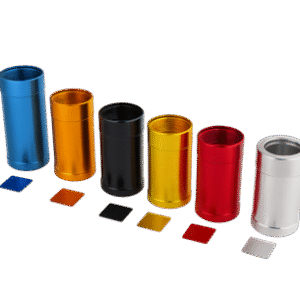

Surface treatments

We provide a wide range of surface treatment options and ensure that your part finishing meets the required technical specifications. Our capabilities include anodizing, powder coating, plating, painting, passivation, and chromatin.

Plastic injection molding

We manufacture plastic parts using defined processes from design for manufacturing and tooling to prototyping and series production. Injection molding is supported by controlled parameters to ensure stable and repeatable output. We also use vacuum casting and silicone molding for early development phases, functional samples, and low-volume production where flexibility and fast turnaround are required.

Forming & casting

We produce metal parts using forging, die casting, and extrusion, managing the process from tooling stage until the first prototype to the series production. Dimensions, material properties, and surface requirements are implemented according to your specifications.

These methods allow us to create raw parts optimized for subsequent CNC machining. Near-net-shape production reduces machining time and helps optimize overall cost.

Cable assembly

We produce cable assemblies based on specified materials, connectors, and electrical requirements. We supply standard connector configurations as well as fully customized solutions created through a customized tooling and over molding process. All cables are electrically and mechanically tested to ensure they integrate into your devices or assemblies without adjustments.

EMS and Electronics

Bicycle and Micro-mobility Industry

Consumer Products

Energy & Utilities

Industrial Equipment

Medical Devices

Where our parts are used?

We supply mechanical parts and assemblies for EMS companies and OEMs.

Our components are used in electronics, industry, energy, medical devices, consumer products and micro-mobility.

When precision matters, we are the right partner.

Impressions

Valve block

CNC machning

Anodizing

AL6061

Locking pin

CNC machning

SUS 304

Spring loaded housing

CNC-machining, Anodizing

Al6061-T6

Housing for PCBA

Lasercutting, Bending, Stud pressing, Powdercoating

Galvanized steel

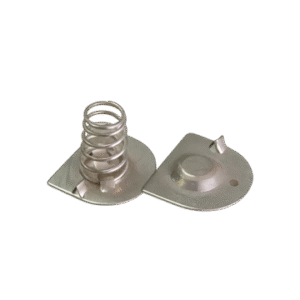

Battery spring contact

Progressive metal stamping, spring forming

SUS 301

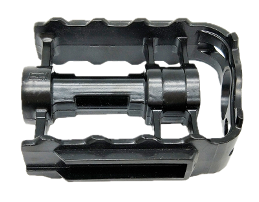

Bicycle pad

Die casting, CNC machning,

Sand blasting, Painting

A385

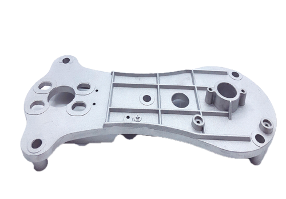

Gearbox cover

Die casting, CNC milling, Sand blasting, Chromating

AlSi9Cu3/ ADC12

AR/ AF Lens

Precision pressing, Grinding, Coating

Glass

Custom cable assembly

Cable assembly + over molding

TPU, PVC, TPE

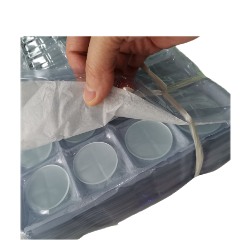

Sealings

Compression Moulding

EPDM

Rawmat for CNC machining

Hot forging

AL6061

You are looking for something else?

Share your idea with us, we’ll look into it together